|

| Feed screw maintenance. |

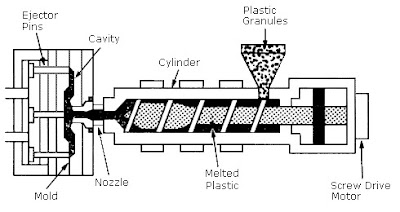

Plastics industry feed screws, or feed screw augers, are mechanisms that use rotating helical screw blades to move plastics pellets through the barrel of molding and extrusion equipment. The feed screw transports the plastic as it changes phase from solid to viscous liquid through friction, shear, and conductive heat transfer.

A typical feed screw has three zones. Plastic pellets enters the screw feed section where the pellets are compacted and conveyed. Next is the transition (or compression) section, where the plastic is compressed, conveyed, and melted. Finally, the liquid plastic moves to the metering section where it is precisely controlled at optimum temperature and viscosity.

For more information about feed screws, or any part of the injection molding process, contact:

508-351-6200

|

| Diagram of injection molding process. |