Feed screws, also known as extruder screws, play a crucial role in the melt stream process of the plastics industry. The melt stream process transforms raw plastic materials into a continuous, homogenized, and viscous molten mass, which can be further shaped and processed into various products like films, sheets, pipes, profiles, and more. The feed screw is an essential component of the extruder machine, the primary equipment used in the melt stream process.

The role of the feed screw in the melt stream process is explained in detail by understanding its different sections and their functions:

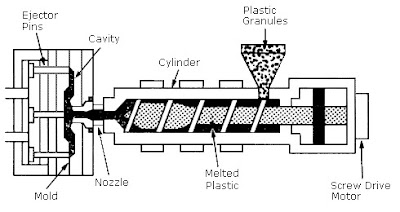

- Solid conveying (feed) zone: The feed screw consists of a helical channel or flights with a rotating shaft that runs along its length. The screw begins with a hopper where raw plastic material, usually pellets or granules, is loaded. The rotation of the screw transports the raw material forward, creating a solid conveying zone. The screw geometry in this zone efficiently moves the plastic material toward the subsequent zones.

- Compression (transition) zone: The depth of the screw channel decreases gradually in this zone, causing the plastic material to compress. This compression generates heat through friction, which melts the plastic along with external heating elements. At the same time, the screw design ensures proper mixing and homogenization of the plastic materials.

- Melting (metering) zone: This zone is characterized by a constant channel depth, where the plastic material becomes fully molten. The screw's geometry creates a uniform and consistent melt flow while providing sufficient back pressure to ensure the homogenization of the molten plastic. Additional mixing elements may be incorporated into the screw design to enhance mixing and homogenization further.

- Discharge (melt) zone: In this final zone, the screw conveys the molten plastic towards the extruder die, designed to shape the material into the desired product form. A screen pack and breaker plate are typically placed before the die to filter out contaminants and ensure a uniform melt flow.

Feed screws play a vital role in the overall efficiency and quality of the melt stream process. The design of the screw and its various geometries can significantly affect the processing conditions, output rate, and final product quality. Different types of feed screws are available, tailored to the specific requirements of the plastic materials and end products, such as single-screw, twin-screw, and multi-screw extruders. These screws may also be classified based on their compression ratio, screw profile, and mixing elements.