Certain maintenance and cleaning measures should be performed to ensure the long-term durability and accuracy of your Dynisco pressure sensor. This video demonstrates how to remove, care for, and maintain a Dynisco pressure sensor from an extruder.

This video explains the proper removal, care, and maintenance process of an extruder's Dynisco pressure sensor.

Do not attempt removal of the sensor while there is pressure in the process still, as this could cause polymer ejection through the sensor mounting hole.

The technician will unscrew the sensor from the extruder. Ensure that you are wearing proper safety equipment while removing the sensor. Dynisco recommends the sensors are removed from the process while hot. The technician then wipes clean the sensor immediately with a cotton rag. Dynisco does not recommend the use of sharp tools, screwdrivers, or wire brushes for removing polymers. With the diaphragm free of material, the technician examines the tip for damage or deformations. Damage may appear as a depression or a bubble on the diaphragm. Any deformation may affect the pressure reading. Dynisco recommends the sensor be sent back for evaluation by our repair department upon discovery of damage.

With the sensor removed, the focus is now on material that has entered the threaded area and the 45-degree seat—using the Dynisco mounting hole cleaning tool kit. The kit consists of a four fluted cleaning drill for cleaning the ½ 20 UNF threads and then a unique tool for cleaning the 45-degree seat (guide sleeve and T handle).

The technician will manually spin both tools into the mounting hole threads to remove polymer residue and other materials. After the hole is clean, the technician uses the gage plug included in the kit to check the mounting hole for contact points via the Dykem machine blue. The Dykem should not be missing around the edge of the tip; only the 45-degree seat will make contact. If contact appears on the outer diameter of the tip, then there is potentially pressure building on the sensing end of the sensor, which can cause damage, such as depressions or bubbles.

Once the mounting hole and contact points are confirmed clean, reinstall the sensor into the process, paying attention to the correct mounting torque. For the ½ 20 UNF threaded pressure sensor, the recommended torque is 100 inch-pounds. Hand-tight and a quarter turn is the best practice. Over torque can cause the threads to gall. If your sensor is over-torqued, use anti-seize to aid in the future removal of the sensor. Heat the pressure sensor to the proper temperature before re-pressurizing the extruder.

Proper care and maintenance of your sensors and mounts are essential for reducing operating costs and prolonging the lifespan of your sensors.

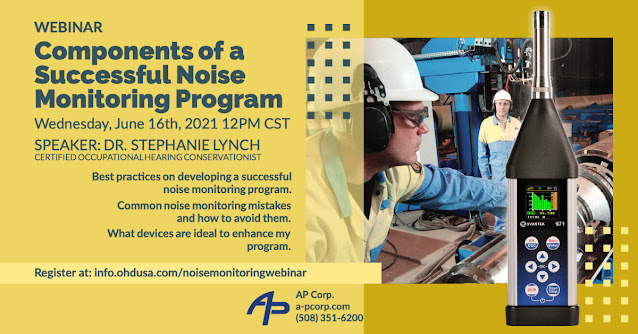

For more information on Dynisco products in New England and Upstate New York, contact AP Corp. Call (508) 351-6200 or visit https://a-pcorp.com.