|

| Photo 1 - Recycled Plastic with Color |

INTRODUCTION

Color measurement is a well-accepted technology to check the quality of the color values in the production process. Usually these measurements are performed "off-line".

The delay between sampling and obtaining the results from the laboratory can be time consuming. A significant disadvantage is that only a single measurement is generated in this time period and the quality of the color during, before and after the sampling point is unknown.

With the in-line color measurements taking place directly in the melt, not only is complete documentation possible, but when color variations occur, immediate intervention can take place.

|

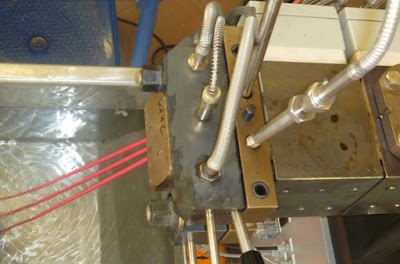

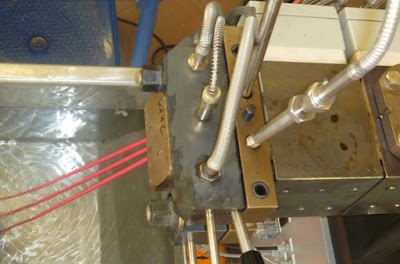

| Photo 2 - Reflection probe in strand pelletizer. |

When recycling plastic to convert to new uniform colored pellets many challenges can take place. Recycled plastic is much more inconsistent than virgin material. Understand-ing this inconsistency will help on your color dosing to provide a more homogeneous final product. With the proper color measurement system you can know the color values of your extrudate in real time. This allows for closing the loop on your color by changing your dosing rates to meet your specifications.

INNOVATIVE NEW TECHNOLOGY

|

| Photo 4 - Stainless Steel NEMA4 box with touch-screen. |

Technology from

Equitech, a manufacturer of in-line process instrumentation, deploys a probe directly in the molten polymer. Their

Reflection Polymer Melt Probe (RPMP, Photo 2) is installed on the exit (adapter) of the extruder by using ½”-20 UNF thread (typically Dynisco®). The RPMP is screwed into position in the adapter between the extruder and the die. The RPMP consists of the threaded body and optical fibers. The sapphire lens on the tip of the probe is the observation window and is very well suited to the harsh conditions in the extruder (temperature, pressure, and friction through flowing material). The self-cleaning function of the sapphire is ensured by the shear force of the material flow. Ideal installation is directly into the melt stream in the adapter.

Off-line measurements are used more effectively by downloading them to the

Equitech Inline Color Spectrophotometer. This can be done manually or through OPC communications. By having the laboratory target values displayed on the Equitech system the operator can view trends of L*, a*, b* and Delta E.

This method provides complete documentation of a particular extrusion run. It also matches the known laboratory measurements giving confidence that an extrusion run has maintained specifications throughout its entirety. When color variations occur, notification can take place via digital alarms. Intervention can take place via OPC or analog signals i.e. L* feedback for closed loop color control.

|

| Photo 3 - Trend charts of EquiColor Software |

COLOR MEASUREMENT

Illumination of the polymer through the sapphire window is achieved by 6 circumferentially-positioned glass fibers which convey the light of a xenon flash lamp. The reflection from the illuminated surface is detected by one center-positioned optical fiber. This reflected light is then interpreted by the spectrophotometer. Color values such as L*, a*, b* C*, h are calculated from this spectral curve, and displayed as trend charts, (see Photo 3).

For a continuous process monitoring, 10 to 60 seconds is recommended as the measurement interval. Intervals as fast as 1 to 2 seconds are possible. The calibration of the spectrophotometer is designed specifically for the demands of the production process. Calibration can be done without interruption of the process.

USER BENEFITS

- Real-time information about process stability & quality

- Impact of speed changes on the quality of the extrusion

- Controlled color changes: start phase, end of run

- Avoid off-specification batches & waste production

- Detection of dosage elevations

- Optimized recipe formulation & process design

- Available feedback loop for L* closed loop control via feeder

- Comprehensive quality audit trail customer documentation

For more information, contact

AP Corp. by calling

(508) 351-6200 or visiting

https://a-pcorp.com.

Reprinted with permission from Equitech International Corporation.