|

| Various types and styles of temperature sensors (Pyromation). |

This post describes the three most popular temperature sensors, how they function, and where they are used.

THERMOCOUPLES

|

| Thermocouple illustration showing base metal designs with various types of junctions (Pyromation). |

effect. In the simplest terms, thermocouples produce a micro-voltage between two conductors - joined at each end and made of dissimilar metals - when one junction varies in temperature and the second junction (called the reference junction) is known and maintained at a constant temperature. The corresponding voltage produced at the sensing junction can be measured and directly correlated to the change in the sensing junction's temperature.

Thermocouples are popular and widely used in industrial and commercial temperate systems because they are:

- Cost-effective.

- Provide good accuracy.

- Have a sufficiently linear temperature-to-signal output curve.

- Are available in many different metal alloys for many different temperature ranges.

- Are easily interchangeable.

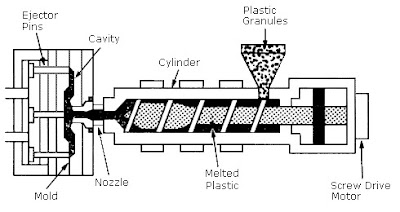

Thermocouples are commonly found in many industrial processes. Examples are the plastics industry, primary metals, power generation, kilns, industrial boilers, HVAC, gas turbine exhaust systems and and diesel engines. And because they are affordable and easy to produce, thermocouples are also used in many consumer applications, such as residential and commercial cooking and heating equipment.

RTDs

|

| Wire wound RTD (Image courtesy Wikipedia) |

RTD’s are popular because:

- They offer considerably higher accuracy and repeatability than thermocouples.

- Can be used up to 600 Deg. Celsius.

- Can be integrated directly on the part to be monitored.

|

| Thin-film RTD (Image courtesy of Wikipedia) |

THERMISTORS

Another very common temperature sensing device is the thermistor. Thermistors are also a resistance measuring device similar to RTD’s. However, instead of using a pure metal as the resistance element, thermistors employ a very inexpensive polymer or ceramic resistance element. While these materials are very cost-effective, the downside is the resistance-to-temperature output curve. The change in resistance to a corresponding temperature change is very non-linear, and as such, make thermistors' use practical only within a narrow temperature range.

Thermistors are very inexpensive and have a very fast response making them very attractive in applications where a narrow sensing range exists and cost is important. Thermistors also come in two varieties, PTC, or positive temperature coefficient, and NTC, or negative temperature coefficient. PTC's resistance increases with increasing temperature, while NTC's resistance decreases with increasing temperature.

Thermistors are used widely in food processing in digital thermostats, and for on-board temperature monitoring of electronics and circuit boards. They are also used widely in many consumer appliances.

For more information on any temperature sensing application, contact AP Corp and discuss your requirement with one of their experienced application experts. They can be reached at (508) 351-6200 or visit them at https://a-pcorp.com.