So how do I choose the right melt pressure sensor for my application?

A sensor is defined through the following specifications:

- Pressure Range

- Process connection

- Electrical output and connection

- Capillary configuration (rigid/flexible)

There are more variables come into play, but let's focus on these four since they are the most critical.

Melt Pressure Sensor Pressure Range

The pressure inside a plastics processing machine can usually be estimated well enough to determine a sensor's good pressure range. The typical working pressure should be within 20%-80% of the sensor's pressure range to balance accuracy and lifetime.

Melt Pressure Sensor Process Connection

For threaded connections in plastics processing, a standard has developed over time, which is the ½"-20UNF thread with a conical sealing face. There might be situations where different thread sizes or a flange connection is required. There are numerous options available from manufacturers, such as

Dynisco, to satisfy customer needs regarding the process connection.

Melt Pressure Sensor Electrical Output

A pressure sensor is an electro-mechanical device that converts a mechanical effect (pressure deflects a thin piece of metal) into an electrical signal through a strain gauge. The strain gauge changes its resistance by following the deflection of the metal piece. In the simplest case, the strain gauge signal can be used directly to feed a read-out device to display the pressure. In order to accommodate industry-standard equipment, such as process control equipment, manufacturers like

Dynisco supplies sensors with different amplified output options such as 4-20mA or 0-10V.

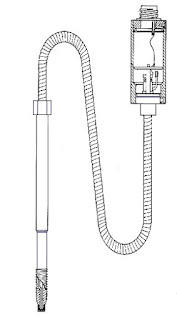

Melt Pressure Sensor Capillary Configuration

A typical pressure sensor has a liquid-filled capillary that connects the process-connection diaphragm (which is deflected by the process pressure) and the measuring diaphragm (where the strain gauge is bonded). This capillary is necessary to create a heat barrier, as the strain gauge cannot withstand the typical process temperatures at plastics processing. Also, the sensor's electronics need to be kept away from heat sources as well as possible. To find a suitable mounting location for the electronics, countless combinations of the rigid stem and flexible connection lengths are available.

Other Considerations in choosing a Melt Pressure Sensor:

- Diaphragm materials

- Diaphragm coatings

- Approvals and certifications

For assistance in selecting or applying any plastics molding equipment, contact

AP Corp. by calling

(508) 351-6200 or visit their website at

https://a-pcorp.com.