A blog discussing sensors and instrumentation. New products, new technologies, and interesting applications. Types of sensors and instruments discussed include: Analyzers, Color Sensors, Displacement Sensors, Flow Sensors, Industrial Weighing, Instrumentation (Data Acquisition), Load Cells & Instrument Hardware. Machine Controls, Pressure Gauges, Pressure Sensors, Sanitary Sensors, Strain Gages, and Temperature Sensors. Courtesy of AP Corp.

Dynisco Cloud Connect™

With the new Dynisco Cloud Connect™ through Microsoft® Azure – you get a single cloud solution that aggregates all your device(s) data into one place that is secure, reliable, easy to share, with 24/7 support.

The Dynisco Cloud Connect can be used for one product or entire global production lines –whether across the street or across the globe giving you easy access to manage data across the cloud, no matter where it lives. This solution is easily expandable and is even compatible with multiple brands and equipment types, from sensors to melt flow indexers to rheometers. With Dynisco Cloud Connect, you can compare and correlate data between facilities and be able to monitor and adjust parameters in real-time, from a mobile device anywhere in the world, whether working in the field, on the production floor, or in the office.

For more information about Dynisco products in New England and Upstate New York, contact AP Corp. Call them at (508) 351-6200 or visit their website at https://a-pcorp.com.

Process Weighing, Web Tension, and Force Control Systems Applications in Pulp and Paper Production

DOWNLOAD THE BLH PULP & PAPER APPLICATIONS GUIDE HERE

Pulp and Paper Applications

- State-of-the-Art Instrument for Weighing and Force Measurement

- Web Tension Measurement Unit

- Dynamic Resultant Force Measurement

- Refiners Position and Pressure Control

- Paper Rolls, Pulpers and Coating Kitchen

Micro-Measurements Strain Gage Instrumentation Catalog

Explore Micro-Measurements complete catalog of data acquisition instruments.

Micro-Measurements offers a comprehensive range of specialty instruments for data acquisition. With Micro-Measurements instruments, you can capture fully corrected, accurate engineering-unit data with minimal effort. Their special-purpose equipment, backed by highly skilled engineers' expertise and knowledge, complements strain gage installation integrity and instrument calibration.

Product Range:

- High-speed data loggers

- Single-channel devices

- Portable indicators

- Multi-channel data acquisitions systems

- High-bandwidth signal conditioners

- Signal conditioning amplifiers

- Embedded analog-to-digital convertors

- Inputs for other commonly used sensors, including load cells, displacement transducers, thermocouples, and accelerometers.

The QSO® Quick Shut-off Valve from Glycon Corporation

A better quick shut-off non-return valve for the Plastics Industry.

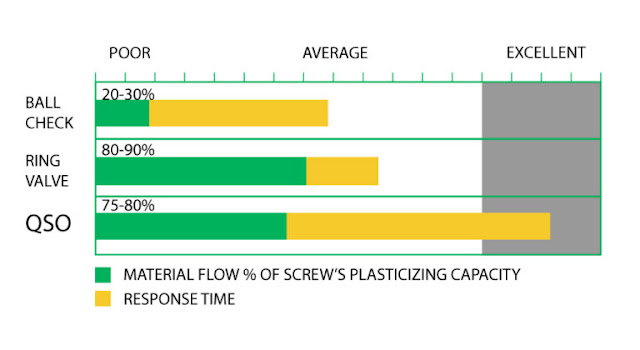

Injection molding applications require two important criteria from a non-return valve:- Rapid material shut off for part weight consistency

- A smooth, high-flow profile to prevent material degradation.

The Glycon QSO® valve is the only valve that provides you both. The result is higher quality parts, fewer rejects, improved yield, and a better return on every pound of material you run.

Compared to traditional ball and ring check valves, only the QSO® Quick Shut-off Valve delivers both high flow and raid shut-off. Plastics molders prefer the QSO® because:

- The QSO® ends short shots!

- The QSO® reduces scrap rates

- The QSO® optimize part weight consistency

- The QSO® prevents material degradation

- The QSO®is perfect for filled materials

- The QSO® eliminates need for decompression or “suck back”

- The QSO® maintains smooth material flow path

- The QSO®is designed for long lasting and durable

Which Melt Pressure Sensor Is Good for My Application?

So how do I choose the right melt pressure sensor for my application?

A sensor is defined through the following specifications:

- Pressure Range

- Process connection

- Electrical output and connection

- Capillary configuration (rigid/flexible)

There are more variables come into play, but let's focus on these four since they are the most critical.

Melt Pressure Sensor Pressure Range

Melt Pressure Sensor Process Connection

Melt Pressure Sensor Electrical Output

A pressure sensor is an electro-mechanical device that converts a mechanical effect (pressure deflects a thin piece of metal) into an electrical signal through a strain gauge. The strain gauge changes its resistance by following the deflection of the metal piece. In the simplest case, the strain gauge signal can be used directly to feed a read-out device to display the pressure. In order to accommodate industry-standard equipment, such as process control equipment, manufacturers like Dynisco supplies sensors with different amplified output options such as 4-20mA or 0-10V.

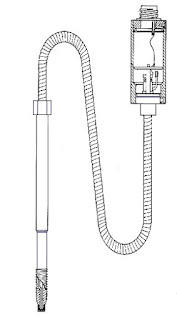

Melt Pressure Sensor Capillary Configuration

A typical pressure sensor has a liquid-filled capillary that connects the process-connection diaphragm (which is deflected by the process pressure) and the measuring diaphragm (where the strain gauge is bonded). This capillary is necessary to create a heat barrier, as the strain gauge cannot withstand the typical process temperatures at plastics processing. Also, the sensor's electronics need to be kept away from heat sources as well as possible. To find a suitable mounting location for the electronics, countless combinations of the rigid stem and flexible connection lengths are available.

Other Considerations in choosing a Melt Pressure Sensor:

- Diaphragm materials

- Diaphragm coatings

- Approvals and certifications