The following is the transcript from the podcast "

StrainBlog" (

https://www.strainblog.com) about

exciting new technology for adding lead wires to strain gages. The discussion between hosts Jim and Darryl is about the development and virtues of the new

Advanced Sensors Technology C4A and C5K strain gages.

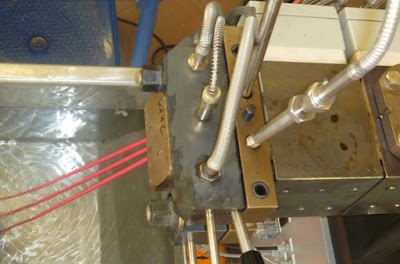

Jim - The topic that keeps coming up repetitively is gauges with pre-attached lead wires. I got a myriad of customers looking for a variety of different solutions. Everything from printed circuit boards, where we've got to route very fine lead wires from gauges to data acquisition systems; civil engineering projects where they're looking for low cost, long cable lengths, sometimes two wires, sometimes three wire. There seem to be more and more demands - what are we doing to meet this variety of applications that we sort of lump into this category of pre-leaded strain gages?

Darryl - Jim, that's a fantastic question. So, we've got this new line of strain gages we call

C4A's [from

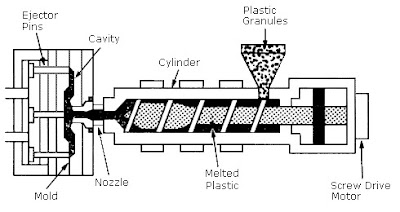

Micro-Measurements], and they they're available in a bunch of different sizes. We go down right now to about a 0.062" gage length, and we go up to a 0.235" gage length. We put a two conductor and a three conductor wire on it on. We can vary the length of that, and these gages are actually made using our new technology from the Advanced Sensors Group, where we can really push the limits now both on the size of the strain gage as well as the resistance. We're really excited about these. We're targeting different markets, including structural testing, as well as printed circuit board testing. There's also another one that we've recently introduced, which is a C5K version, and that's a three element rosette, a planar style that's in a 350 Ohm resistance, and with this new technology, we can make this gauge smaller, more compact than ever before, and it really makes it ideal for printed circuit board testing, where you're trying to get up close to the components that's on that board, so that you could get very accurate, localized strain gage measurements.

Jim - Now, I think I've seen one of the

C5K gages that you refer to, and that's a remarkably small planar gage. If I'm correct, the footprint of that planar gage is even smaller than the smallest stacked rosette that we've ever made. Is that true?

Darryl - Yeah, you're absolutely right. So, one of the smallest stacked rosettes we've had is the 031WW as well as the G1350, and this new planar gage will actually fit within the footprint of both of those gages. The active gauge length is less than 0.020 of an inch, and we also pre-attach three conductor, 36 gauge wire to each one of those grids, so basically, you have a planar rosette with 10 feet of three conductor Teflon insulated wire that's 36 gauge in size.

Jim - Well that seems to solve a lot of problems. With stacked rosette that you have a lot of self heating issues, trying to dissipate the heat from those three layers, down to a single plane and dissipate that. With the planar rosette, all gauges air on the single plane - you don't have a proximity issue with height of sight from the neutral axis, you don't have that heat build up, and if I remember correctly, these are actually 350 Ohm gages, not 120.

Darryl - That's absolutely right. You hit the nail on the head. These are 350 Ohm gages, so you don't have to be as concerned about self heating effects, because of the higher resistance, and also because it's a planar, and like you mentioned, there's not as much of a superposition error because that's a planar gage and not a stack one. So there should be less correction due to bending and also less concern related to excitation and self-heating of the strain gage. We're really excited about adding this to our portfolio of strain gauges that customers can use now to do this printed circuit board type testing.

Jim - And that coupled with the fine wires solves a wire routing issue, getting those leads out from between components out of the package to the data acquisition system. Sounds like a perfect solution to me.

Darryl - Yeah, we're really excited about.

For more information on

strain gage sensors with pre-attached leads in New England or Upstate New York, contact

AP Corp. by calling (508) 351-6200 or visit their website at

https://a-pcorp.com.