A blog discussing sensors and instrumentation. New products, new technologies, and interesting applications. Types of sensors and instruments discussed include: Analyzers, Color Sensors, Displacement Sensors, Flow Sensors, Industrial Weighing, Instrumentation (Data Acquisition), Load Cells & Instrument Hardware. Machine Controls, Pressure Gauges, Pressure Sensors, Sanitary Sensors, Strain Gages, and Temperature Sensors. Courtesy of AP Corp.

In-Line Color Measurement in the Molten Polymer

Special Offer - Up To 35% Off a Druck DPI620PC or DPI620SPC Package

The Druck DPI 620 is a sophisticated multi-function calibrator and HART/Foundation Fieldbus communicator combined to provide a world-class pressure measurement and generation. For usage in hazardous places, ATEX and IECEx approved intrinsically safe versions are available.

Druck is offering a special promotion. Get 35% off when you purchase a DPI620PC or DPI620SPC package.

A DPI620PC package is defined as one of the following:

- Safe Area - PN DPI620PC-2barg, DPI620PC-7barg, DPI620PC-20barg

- Hazardous Area - PN DPI620SPC-2barg, DPI620SPC-7barg, DPI620SPC-20barg

- HART capability, Safe Area - PN DPI620PC- H-2barg, DPI620PC-H-7barg, DPI620PC-H-20barg

- HART Hazardous Area - PN DPI620SPC-H-2barg, DPI620SPC-H-7barg, DPI620SPC-H-20barg

All include Druck’s latest 4Sight2 software for up to 35% off the combined list price of the individual products.

For more information in New England, contact AP Corp. Call (508) 351-6200 or visit https://a-pcorp.com.

Webinar: Components of a Successful Noise Monitoring Program - June 16, 2021

AP Corp. is pleased to provide details for an upcoming webinar presented by OHD (Occupational Health Dynamics) and SVANTEK on implementing and operating a successful sound monitoring program.

In this 1-hour webinar, OHD's Certified Industrial Hygienist, Dr. Stephanie Lynch, will go over regulations, best practices, common downfalls, and much more when successfully building and enhancing your companies noise monitoring program.

Stephanie Lynch is a Certified Occupational Hearing Conservationist and has over 15 years of Occupational Safety and Industrial Hygiene experience. Her doctoral dissertation research involved the collection of personal noise dosimetry and whole-body vibration measurements. Her research carries into the real world in manufacturing and military applications.

SVANTEK is the leading brand of sound and vibration meters for occupational health and safety, environmental noise, human vibration, and building vibration.

To register, visit this link (https://info.ohdusa.com/noisemonitoringwebinar).

Dynisco Polyclean Fluidized Baths

Cost-Effective, Fast, and Safe Way to Clean Various Plastic Processing Components

The Dynisco PolyClean Fluidized Temperature Baths come in three models and offer a cost-effective, fast, and safe way to clean various plastic processing components. PolyClean Fluidized Temperature Baths are applied in any polymer manufacturing or laboratory facility that needs minimal operator interaction and a low risk of harm to essential design requirements of a part during the cleaning process.

The PolyClean 6L Fluidized Temperature Bath is ideal for cleaning small tooling from laboratory extruders or injection molding machines.

The PolyClean 12L cleans extrusion tooling and other forms of hardware, forms parts, calibrates and tests various sensors and systems, heat treats metals and heats reactors, coils, flasks, and containers.

The 26L PolyClean has similar functions and benefits to the PolyClean 12L, but its 26" deep basket allows it to clean larger components than the PolyClean 12L

For more information in New England and Upstate New York, contact AP Corp by calling (508) 351-6200 or visiting https://a-pcorp.com.Now Representing Sensuron - Ultrafine Distributed and Continuous Strain & Temperature Sensing

AP Corp is pleased to announce its selection as Sensuron's New England and Upstate New York Authorized Representative.

ABOUT SENSURON

Starting as an informal partnership with NASA and a formal licensing agreement in 2011, Sensuron began developing off-the-shelf fiber optic sensing systems and then designing cutting-edge fiber optic sensing platforms that allowed companies to consolidate their testing and measurement solutions. Sensuron is now a leading global provider of distributed strain and temperature sensing platforms for applications across industries and is now expanding to liquid-level and 2D deflection.

Sensuron's fiber optic sensing technology enables engineers to perform structural testing, design optimization, structural health monitoring, thermal mapping, and shape sensing with an efficient, robust, and simple-to-use tool.

AP Corp is proud to be representing Sensuron in all of New England and Upstate New York. For more information call (508) 351-6200 or visit this web page.

AP Corp.One Tara Boulevard

Suite 200

Nashua, NH 03062

www.a-pcorp.com

508-351-6200 (office)

Combat the Hazards of Plastics Screw and Barrel Wear

Industrial-grade screw and barrel wear cuts throughput speeds, producing scrap before shutting down. For the first time, technology is making progress in unraveling the mystery of screw and barrel wear.

There has been a lot of injection molding machine innovation in the past year. And now, Glycon Corp. has the technology to test wear within the plasticating device. Glycon is in the first phase of rolling this technology out in the industry. It will concentrate on extrusion and blow molding.

With this capability, they have developed the technology to calculate the rate of wear and predict future wear. This data determines the most cost-effective time to replace these components.

Glycon has been working on measuring wear since 1986 gained their first patent as Great Lakes Feedscrews. The company expanded the invention to include measuring barrel wear and was awarded additional patents in 2006, 2007, 2008, and 2019.

Wear and tear challenges are well documented over the years, and plastic processors know the symptoms. Many machine operators compensate by making changes to the screw speed or temperature settings. The problem is, both of these changes would ultimately result in lower efficiency and higher scrap rates.

The new system called EMT (short for Electronic Measurement and Tracking), includes Glycon's flite-scan eddy-current sensors mounted in one or more positions within a SmartBarrel. These barrels also have SmartPorts, another innovative technology offered by Glycon.

Measurements will be conducted routinely at the processor's plant by field technicians using a Flite-Scan sensor. Several eddy-current sensors were tried over the years. Multiple sensor manufacturers were collaborated with, but all ran into failure at high temperatures in the plasticating units.

Micro-Epsilon, a leading manufacturer of sensors that measure displacement, distance, position, vibration, dimension and thickness, was the eventual choice because their sensors proved much more robust and provided reliable readings up to 600 F.

The EMT system is not only to analyze the data to determine the optimum time to replace or repair worn screws or barrels to optimize productivity but also to relate the wear to:

- Materials of screw/barrel construction.

- Screw/barrel alignment.

- Polymers being processed.

- Impact of abrasive fillers.

- Performance related to wear, including production rates, cycle times, energy consumption, melting rates, head pressures and melt temperatures.

The Glycon EMT system's advantages are that it provides precise measurement of the wear on the OD of the feedscrew and the barrel's ID and its simplicity and cost-effectiveness. It allows maintenance personnel to plan to measure intervals and to schedule changeouts at convenient times based upon wear-rate data rather than 'running to failure' and having to run inefficiently or not at all.

For more information about the new Glycon technology in New England and Upstate New York, contact AP Corp. Call them at (508) 351-6200 or visit their website at https://a-pcorp.com.

AP Corp. Selected Druck New England Representative

AP Corp. is delighted to announce that they are now the New England Sales and Engineering Representative for Druck piezo-resistive pressure sensors and test/calibration instruments.

Druck, a Baker Hughes business, manufactures the high-reliability piezo-resistive pressure sensors and test and calibration instruments known for performing in the most challenging environments. Their products provide customers with the highest performance, stability, quality, accuracy, and quickest response in any environment.

Druck's product line includes pressure sensors, OEM custom sensors, PACE Pressure Controllers, handheld process calibrators, pressure indicators, test tool instrumentation, and 4Sight2 Calibration Management Software.

The addition of Druck extends AP's offering of high quality, best-in-class, engineered sensor solutions. AP Corp's application expertise and long-standing customer relationships in New England are vital to providing Druck with accelerated sales growth in this territory.

For more information, contact:

AP Corp.

One Tara Boulevard

Suite 200

Nashua, NH 03062

www.a-pcorp.com

508-351-6200 (office)

Distance Measurement for Reflecting Surfaces with Universal Laser Sensor

Plastics, mirrored glass, or metals have highly reflective surfaces and require special laser sensors to measure displacement and distance. Displacement and distance measurements on strongly reflecting surfaces challenge conventional, diffuse reflection laser sensors.

Laser sensors such as the Micro-Epsilon optoNCDT 1750DR provide a real-time surface compensation feature that controls exposure time that produces stable signals. This type of laser sensor operates on the principle of direct reflection, aligned so that the angle of incidence is equal to the angle of reflection. Proprietary algorithms compensate for the back-scattered, high-intensity light—all of this in a compact design, including an integrated controller (no external control unit is required).

Mounting and wiring are easy. A mounting template enables the user to align the sensor correctly. The laser class 1 rating on which the optoNCDT 1750DR operates is another advantage. Additional safety precautions are not necessary since the emitted laser power does not exceed 390 µW. Users have the choice of an intuitive web interface which can operate the laser sensor from a browser.

For more information in New England, contact AP Corp.

Do You Have a Production Part Heating Challenge? Get Free Assistance from The LAB

Ambrell's Applications Laboratory, known in the industry as THE LAB, will solve your most challenging heating applications. They will provide recommendations for precision induction heating solutions for parts of every size, shape, and material composition.

THE LAB will apply their state-of-art testing facility, fully equipped with Ambrell induction heating systems and hundreds of proven coils. You can also interface with their engineers and see first-hand how they design prototype coils and develop innovative, practical solutions to maximize your heating process's efficiency.

The process is easy. Just follow these three steps:

- Send THE LAB your parts and process requirements.

- Their engineers will analyze your process and heat your parts to develop the right solution for your specific application.

- You will receive your parts back for inspection, as well as a video of the heating process and a laboratory report with a system recommendation.

You have the option to observe testing through Ambrell's Remote Lab Service from the convenience of your office.

If you have old systems that need upgrading, why not find out if using a smaller, more efficient Ambrell induction heating system is the right solution for your process? There are measurable savings in less downtime, higher production throughput, improved energy efficiency, and more.

To learn more in New England and Upstate New York, contact AP Corp. Call them at 508-351-6200 or visit their website at https://a-pcorp.com.

Process Weighing, Web Tension, and Force Control Systems Applications in Pulp and Paper Production

DOWNLOAD THE BLH PULP & PAPER APPLICATIONS GUIDE HERE

Pulp and Paper Applications

- State-of-the-Art Instrument for Weighing and Force Measurement

- Web Tension Measurement Unit

- Dynamic Resultant Force Measurement

- Refiners Position and Pressure Control

- Paper Rolls, Pulpers and Coating Kitchen

Micro-Measurements Strain Gage Instrumentation Catalog

Explore Micro-Measurements complete catalog of data acquisition instruments.

Micro-Measurements offers a comprehensive range of specialty instruments for data acquisition. With Micro-Measurements instruments, you can capture fully corrected, accurate engineering-unit data with minimal effort. Their special-purpose equipment, backed by highly skilled engineers' expertise and knowledge, complements strain gage installation integrity and instrument calibration.

Product Range:

- High-speed data loggers

- Single-channel devices

- Portable indicators

- Multi-channel data acquisitions systems

- High-bandwidth signal conditioners

- Signal conditioning amplifiers

- Embedded analog-to-digital convertors

- Inputs for other commonly used sensors, including load cells, displacement transducers, thermocouples, and accelerometers.

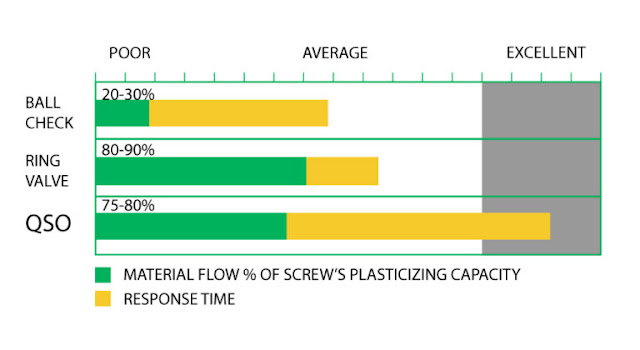

The QSO® Quick Shut-off Valve from Glycon Corporation

A better quick shut-off non-return valve for the Plastics Industry.

Injection molding applications require two important criteria from a non-return valve:- Rapid material shut off for part weight consistency

- A smooth, high-flow profile to prevent material degradation.

The Glycon QSO® valve is the only valve that provides you both. The result is higher quality parts, fewer rejects, improved yield, and a better return on every pound of material you run.

Compared to traditional ball and ring check valves, only the QSO® Quick Shut-off Valve delivers both high flow and raid shut-off. Plastics molders prefer the QSO® because:

- The QSO® ends short shots!

- The QSO® reduces scrap rates

- The QSO® optimize part weight consistency

- The QSO® prevents material degradation

- The QSO®is perfect for filled materials

- The QSO® eliminates need for decompression or “suck back”

- The QSO® maintains smooth material flow path

- The QSO®is designed for long lasting and durable

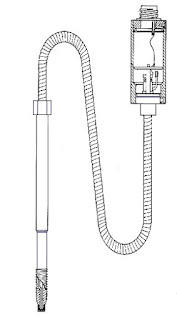

Which Melt Pressure Sensor Is Good for My Application?

So how do I choose the right melt pressure sensor for my application?

A sensor is defined through the following specifications:

- Pressure Range

- Process connection

- Electrical output and connection

- Capillary configuration (rigid/flexible)

There are more variables come into play, but let's focus on these four since they are the most critical.

Melt Pressure Sensor Pressure Range

Melt Pressure Sensor Process Connection

Melt Pressure Sensor Electrical Output

A pressure sensor is an electro-mechanical device that converts a mechanical effect (pressure deflects a thin piece of metal) into an electrical signal through a strain gauge. The strain gauge changes its resistance by following the deflection of the metal piece. In the simplest case, the strain gauge signal can be used directly to feed a read-out device to display the pressure. In order to accommodate industry-standard equipment, such as process control equipment, manufacturers like Dynisco supplies sensors with different amplified output options such as 4-20mA or 0-10V.

Melt Pressure Sensor Capillary Configuration

A typical pressure sensor has a liquid-filled capillary that connects the process-connection diaphragm (which is deflected by the process pressure) and the measuring diaphragm (where the strain gauge is bonded). This capillary is necessary to create a heat barrier, as the strain gauge cannot withstand the typical process temperatures at plastics processing. Also, the sensor's electronics need to be kept away from heat sources as well as possible. To find a suitable mounting location for the electronics, countless combinations of the rigid stem and flexible connection lengths are available.

Other Considerations in choosing a Melt Pressure Sensor:

- Diaphragm materials

- Diaphragm coatings

- Approvals and certifications

Web Tension Control in Paper Production

BLH Nobel web tension systems comprise off-the-shelf standard modules and electronics, as well as customized systems. BLH Nobel designs force measurement modules according to the customers’ mechanical requirements and forces, ranging in size from just a few Newtons to mega-Newtons. The combination of digital signal amplifiers and stable force transducers means that BLH Nobel systems can handle anything from applications with a low tare and large forces, to those with a large tare and small forces.

For more information about BLH Nobel products in New England, contact AP Corp. Call them at (508) 351-6200 or visit their website at https://a-pcorp.com.

EASYHEAT Induction Heaters from Ambrell Corporation

Flameless, non-contact induction heating minimizes energy waste by focusing energy only on the part and zone to be heated. Select and monitor power levels from the front panel LCD and sealed touch pad. Remote power control is available for employing contact inputs, analog inputs or optional serial data port. Easily control the length of the heating cycle with a built-in programmable digital timer.

Download the Ambrell EASYHEAT® 500 Watt to 10 kW Induction Heater Catalog here.

For more information about Ambrell products in New England, contact AP Corp. Call them at 508-351-6200 or visit their website at https://a-pcorp.com.New Bench Top Series of Shaker Systems from Sentek Dynamics

The BT Series shakers from Sentek Dynamics are designed for demanding vibration test applications. Typical applications included structural analysis, calibration and testing of smaller assemblies. The BT-100 through BT-400 shakers utilize light weight rare earth magnets in lieu of traditional Alnico magnets. The use of these magnets decreases the total shaker mass to a third of similar size system, making these shakers easy to handle and portable.

The systems range in size from 100 N (70 lbf) to 1000 N (224 lbf). Systems 400 N (99 lbf) and smaller are permanent magnet shakers and use lightweight rare earth magnets, making these systems easy to handle and portable. There are three versions of the BT Series of shakers: the BT, BT-M and BT-MTH.

The BT Series is recommended for vibration testing of small assemblies and components. These shakers have armature diameters from 60 mm (2.36 in.) to 120 mm (4.72 in.). The BT-1000 is equipped as standard with Automatic Armature Centering (AAC) and Air-Isolation Feet (AIF).

The BT-M and BT-MTH Series are our modal shakers lines. BT-M will use standard stingers while the BT-MTH is our through-hole version. On the 100 N and 200 N system the BT-MTH offers over double the displacement. The BT-MTH Series allow you to use piano-wire stingers. The BT-1000-M is ideal for the structural and modal analysis of high-mass structures. The addition of ZPR (electronic zero-point regulation and adjustable suspension stiffness) allows the user to pre-load the structure prior to applying a dynamic load.

The new Sentek Dynamics Bench Top and modal exciters are based upon years of practical experience. These systems all exhibit a high lateral stiffness and high force-to-weight ratio. They are specifically designed to help ensure the best possible performance with minimum setup time.

Contact AP Corp. regarding any Sentek Dynamics product in New England and Upstate New York. Call us at (508) 351-6200 or visit our website at https://a-pcorp.com.

Micro-Epsilon Laser Profile Scanners: scanCONTROL LLT3000 and 2500

Micro-Epsilon scanCONTROL LLT3000

Micro-Epsilon scanCONTROL 2500

BLH Nobel KIS Beam Load Cell Technology

About Induction Heating

What is induction heating?

Induction heating is a fast, efficient, precise, repeatable, non-contact method for heating metals or other electrically-conductive materials . An induction heating system includes an induction power supply which converts line power to an alternating current, delivers it to a workhead and work coil creating an electromagnetic field within the coil. The work piece is placed in the coil where this field induces a current in the work piece, which generates heat in the work piece. The coil, which is water-cooled and cool to the touch, is placed around or adjacent to the work piece. It does not touch the work piece, and the heat is only generated by the induced current flowing in the work piece.

Induction heating is a fast, efficient, precise, repeatable, non-contact method for heating metals or other electrically-conductive materials . An induction heating system includes an induction power supply which converts line power to an alternating current, delivers it to a workhead and work coil creating an electromagnetic field within the coil. The work piece is placed in the coil where this field induces a current in the work piece, which generates heat in the work piece. The coil, which is water-cooled and cool to the touch, is placed around or adjacent to the work piece. It does not touch the work piece, and the heat is only generated by the induced current flowing in the work piece.Induction heating is used in processes where temperatures are as low as 100 oC (212 °F) and as high as 3000 °C (5432 °F). It can be used in brief heating processes that are on for less than half a second and in heating processes that are on for months.

Induction heating is used in domestic and commercial cooking, and in many applications such as melting, heat treating, preheating for welding, brazing, soldering, curing, sealing, shrink fitting in industry, and in research and development.