A blog discussing sensors and instrumentation. New products, new technologies, and interesting applications. Types of sensors and instruments discussed include: Analyzers, Color Sensors, Displacement Sensors, Flow Sensors, Industrial Weighing, Instrumentation (Data Acquisition), Load Cells & Instrument Hardware. Machine Controls, Pressure Gauges, Pressure Sensors, Sanitary Sensors, Strain Gages, and Temperature Sensors. Courtesy of AP Corp.

Happy Holidays from AP Corp.

"This is my wish for you: peace of mind, prosperity through the year, happiness that multiplies, health for you and yours, fun around every corner, energy to chase your dreams, joy to fill your holidays!" D.M. Dellinger

Plastics Industry Feed Screw Classification White Paper

Glycon Corporation, the industry leader manufacturer of high performance and innovative feed screws, has put together this white paper describing the classifications of feed screws used in the plastics industry.

AP Corp.

https://a-pcorp.com

(508) 351-6200

Labels:

a-pcorp.com,

Connecticut,

CT,

Extrusion,

feed screw,

injection molding,

MA,

Maine,

Massachusetts,

ME,

New Hampshire,

New York,

NH,

NY,

plastics industry,

Rhode Island,

RI,

Vermont,

VT

Polymer Analysis Using ASTM/ISO Method A Testing and the Dynisco LMI5500 Melt Flow Indexer

One of the specific ways to speed development, quality testing, and analysis of polymers is the ASTM/ISO Method A Test using the Dynisco LMI5500 melt flow indexer. This test is used in order to determine flow characteristics of plastic melts are used in various plastic processing techniques, namely extrusion and injection molding.

The LMI5500 brings a new level of ease of use with its removable inspection plate, increased access for sample cutting, and improved touch screen. This device provides values on the melt flow rate melt volume rate and melt density of polymers to ensure that the conditions of production are at peak efficiency without sacrificing the quality of your products. Upon test completion results are viewable, and can be sent to the cloud. The information obtained from this test is important for achieving a quality product while maintaining a high level of efficiency in production.

For more infomration on all Dynisco products, contact AP Corp. Visit their web site at https://a-pcorp.com or call (508) 351-6200.

AP Corp. Salutes Our Veterans

Veterans Day is set aside to honor the men and women who have sacrificed so much in order to serve in the armed forces of the United States.

Veterans Day celebrates and thanks all United States military veterans, alive or dead, and honors the sacrifices that they have made. Our Veterans are our neighbors, friends, family, and co-workers. They took an oath to defend the United States and our Constitution, from all enemies, foreign and domestic. We must never forget their bravery, service, and sacrifice.

Originally called Armistice Day because of the November 11 Armistice that ended World War I, its name was officially changed in the United States in 1954 to Veterans Day to include Veterans of all wars.

Through the observance of Veterans Day, we remind ourselves of our Veterans patriotism, love of country and willingness to serve and sacrifice for the common good.

AP Corp. celebrates and honors America's veterans.

The Badger Meter Cox EC80 Flow Processor

The Cox EC80 Flow Processor is a programmable electronic processor, providing total compensation to enhance flow meter accuracy, while extending the linear flow range. Packaging is provided for remote, direct or embedded mounting to support most installation or application requirements.

The Cox EC80 Flow Processor is a programmable electronic processor, providing total compensation to enhance flow meter accuracy, while extending the linear flow range. Packaging is provided for remote, direct or embedded mounting to support most installation or application requirements.The compact design includes both single and dual frequency inputs from 4 or 10 ohm pickups, as well an RTD input and an additional analog input for other temperature inputs. The EC80 processor tracks all variables to compensate for viscous and inertial effects, using proven Strouhal-Roshko algorithms. Enhanced DSP technology allows for exceptional signal characterization using a 32-bit floating point processor at 150 MHz, capable of producing a 100 microsecond speed of response.

Cox EC80 Flow Processor Applications

- Precision monitoring

- Engine test cells and test stands

- On-board automotive and aerospace testing

- Control loops

- Custom OEM flight and commercial applications

Cox EC80 Flow Processor Industries

- Aviation & Aerospace

- Petrochemical, Refining & Chemical Metering

- Process or Industrial

- Test Equipment & Services

For more information, contact AP Corp. Call them at 508-351-6200 or visit their web site at https://a-pcorp.com.

Labels:

Badger Meter,

Connecticut,

Cox,

CT,

Flow,

flow control,

MA,

Maine,

Massachusetts,

ME,

New Hampshire,

New York,

NH,

NY,

Rhode Island,

RI,

Vermont,

VT

Bonding Strain Gages? 5 Steps to Getting Surface Prep Right!

When bonding Micro-Measurements Advanced Sensors Technology strain gage sensors (CEA, C4A, C5K) you want to ensure an excellent bond. The key element in bonding strain gages is surface preparation.

The video above demonstrates specific procedures and techniques with proven advantages. By precisely following these carefully developed instructions (along with the requisite procedures for gage and adhesive handling), the result will be strong and stable bonds. This video presents a procedure that is simple to learn, easy to perform, and reproducible. Keep in mind, it is very important to pay attention to detail and follow the instructions precisely. The importance of surface preparation for strain gage bonding cannot be understated.

1) Degreasing

Rigorously degrease the gaging area with a good solvent, such as CSM Degreaser or GC-6 Isopropyl Alcohol. Be aware though that some materials (e.g., titanium and many plastics) react with strong solvents. Make sure your solvents do not contain any contaminants2) Abrading

Preliminary dry abrading with 220 or 320-grit silicon-carbide paper is generally required if there is any surface scale or oxide. Final abrading is done by using 320-grit silicon-carbide paper on surfaces thoroughly wetted with M-Prep Conditioner A; this is followed by wiping dry with a gauze sponge. Repeat this wet abrading process with 400-grit silicon-carbide paper, then dry by slowly wiping through with a gauze sponge. Finish with 320 grit on most steels and 400 grit on aluminum alloys.3) Burnishing of Layout Lines

Using a 4H pencil (on aluminum) or a ballpoint pen (on steel), burnish (do not scribe) whatever alignment marks are needed on the specimen.4) Conditioning

Repeatedly apply M-Prep Conditioner A and scrub with cotton-tipped applicators until a clean tip is no longer discolored. Remove all residue and Conditioner by again slowly wiping through with a gauze sponge. Never allow any solution to dry on the surface because this invariably leaves a contaminating film and reduces chances of a good bond.5) Neutralizing

Now apply a liberal amount of M-Prep Neutralizer 5A and scrub with a cotton-tipped applicator. With a single, slow wiping motion of a gauze sponge starting within the clean area and wiping outward in one direction. Repeat the wiping step with a clean gauze pad, again, start in the clean area, wipe though the gage location moving outward in a single stroke to fully dry this surface. Do not wipe back and forth because this may allow contaminants to be redeposited.For proper outcomes, the procedures and techniques presented here should be used with qualified installation accessory products from Micro-Measurements, namely:

- CSM Degreaser or GC-6 Isopropyl Alcohol

- Silicon Carbide Paper

- M-Prep Conditioner A

- M-Prep Neutralizer 5A

- GSP-1 Gauze Sponges

- CSP-1 Cotton Applicators

- PCT Gage Installation Tape

Labels:

Advanced Sensors Technology,

Bonding,

Connecticut,

CT,

MA,

Maine,

Massachusetts,

ME,

Micro-Measurements,

New Hampshire,

New York,

NH,

NY,

Rhode Island,

RI,

Strain Gages,

Vermont,

VT

New Product Alert: A Noise Monitoring Station with Built-in Noise Directivity Detection

The SV 200A is a Class 1 sound level meter integrated with a wireless communication via 3G, LAN, Wireless LAN and Bluetooth®. The list of add-ons also includes a built-in electrostatic actuator, GPS module and e-compass. The waterproof power supply is also provided.

The SVANTEK SV 200A is the top-of-the range noise monitoring station with built-in microphones for noise directivity detection. This innovative, new product enables the identification of dominant noise sources providing information about their location both vertically and horizontally. In practice, measuring directionality gives the opportunity to indicate the dominant source of noise in the measurement area or exclude unwanted events.

Four additional microphones located on the sides of the housing use the sound intensity technique to recognize both the vertical and the horizontal direction of a dominant noise source. Leq distribution in angle sectors is saved as time-history and can be used to filter and report data.

The SVANTEK SV 200A can perform a 1/1 and 1/3 octave frequency analysis in real-time and store it as time-history data. It can also record the audio signal for the recognition of noise sources and recalculation of the data.

The advanced alarm function can send email and SMS notifications caused by threshold levels and time events. Status alarms of the SVANTEK SV 200A are also available.

The 3G modem, Wi-Fi and LAN features provide fast Internet transfer to PC with standard internet connectivity. SvanNET enables Internet plug & play and easy management of measurement projects. Irrespective of the type of a public or private sim card, SvanNET will make a connection to allow full access to your data via Web browser. The Bluetooth ® and Wireless LAN features provide a point of access for easy SvanNET application configuration.

For more information on SVANTEK products in New England and New York, contact AP Corp. Call (508) 351-6200 of visit https://a-pcorp.com.

Labels:

Connecticut,

CT,

MA,

Maine,

Massachusetts,

ME,

New Hampshire,

New York,

NH,

noise monitoring station,

NY,

Rhode Island,

RI,

SV 200A,

Svantek,

Vermont,

VT

The LMI5500 Series Melt Flow Indexer from Dynisco

Specifically, designed for the thermoplastics resin industry the Dynisco LMI5500 Series Melt Flow Indexer has an array of features and benefits that range from ground-breaking accuracy to a unified software platform between all laboratory and online production equipment.

The LMI5500 provides a new level of simplicity of use with its simple to clean inspection plate, accessibility for sample cutting, and improved touchscreen display.

Most notable is its own gravitational correction characteristic that takes into consideration gravity according to the units geographic location.

It is capable of delivering a wide range of data for melt flow rate, shear stress, shear rate, apparent viscosity, intrinsic viscosity, melt density, and testing conditions.

FEATURES OF THE DYNISCO LMI5500 SERIES MELT FLOW INDEXER

For more information about the Dynisco LMI5500 Series Melt Flow Indexer in New England and Upstate New York, contact AP Corporation by calling (508) 351-6200 of visit their web site at https://a-pcorp.com.

The LMI5500 provides a new level of simplicity of use with its simple to clean inspection plate, accessibility for sample cutting, and improved touchscreen display.

Most notable is its own gravitational correction characteristic that takes into consideration gravity according to the units geographic location.

It is capable of delivering a wide range of data for melt flow rate, shear stress, shear rate, apparent viscosity, intrinsic viscosity, melt density, and testing conditions.

FEATURES OF THE DYNISCO LMI5500 SERIES MELT FLOW INDEXER

- Gravitational correction

- New Windows 10 IoT touch screen native interface

- Built in WIFI and ethernet

- HDMI and multiple USB ports

- Direct digital scale USB interface for sample weighing

- Performance meets international standards: ASTM D1238 & D3364, ISO 1133-1, BS2782, DIN 53735, JIS K7210

- Automatic sample cutter for ease and consistency in sample cutting

- Melt Flow Rate to Intrinsic Viscosity correlation for PET

- Nearly unlimited program storage capability

- Increased access to the die for sample cutting with a strategically placed mirror to easily view the die and cutting area

- Supports multiple languages

For more information about the Dynisco LMI5500 Series Melt Flow Indexer in New England and Upstate New York, contact AP Corporation by calling (508) 351-6200 of visit their web site at https://a-pcorp.com.

Gas Turbine Monitoring with Kistler Pressure and Acceleration Sensors

AP Corporation is pleased to present Gas Turbine Monitoring with Kistler Pressure and Acceleration Sensors

Kistler high-temperature measuring systems allow measuring thermoacoustics phenomena in harsh environments with extreme temperatures up to 700°C.

- Safe and reliable operation of gas turbines thanks to combustion dynamics monitoring.

- Differential charge amplifier designed for high temperature sensors.

- High temperature acceleration sensors measuring vibrations.

- High temperature pressure sensors measuring pressure pulsations.

- Reliable monitoring with durable sensors in harsh environments and up to 700°C / 1300°F.

- Predict, monitor and analyze combustion dynamics.

- Complete differential, ground insulated measuring chains enable early detection of smallest pressure pulsations.

- Resistant to high temperature (700°C / 1300°F)

- Ex certified and interference resistant (EMI, RF)

- PiezoStar sensing element - not pyroelectric and no popcorn effect

Labels:

Connecticut,

Kistler,

Maine,

Massachusetts,

New England,

New Hampshire,

pressure,

Rhode Island,

temperature,

turbine,

Vermont

Why Plastics Industry Feed Screws are Designed the Way They Are

|

| Download the white paper here. |

The selection of the proper screw for a given injection molding or extrusion application can be critical to its success.

Screw geometry — length-to-diameter ratio, profile, channel depth, compression ratio, helix angle and a host of special design features — has everything to do with how well the screw performs in a given application.There are documented applications where customers have improved production rates or reduced cycle times by 30 or 40% simply by switching to an improved screw design. Similarly, reject rates have been lowered from more than 4-6% to less than 1% by incorporating a custom designed mixing screw.

And experience shows that the amount of color concentrate required to achieve optimum color mix can be typically reduced from 4% (of the total blend) to 2%, just by using an optimized screw design. When considering resin and concentrate costs, payback for an optimized screw and non-return valve design can be almost immediate.

This white paper, published by Glycon Corporation, provides an in-depth look into plastics industry feed screw design.

Vibration Control Systems from Crystal Instruments and AP Corp.

Crystal Instruments designs, produces, sells, and services hardware and software for machine vibration monitoring, dynamic measurement and environmental testing. The CoCo and Spider instruments have been widely used in machine condition monitoring and diagnostics by taking and analyzing the vibration signals. In the testing lab, professionals use Crystal Instruments products to conduct the measurement and control for vibration, shock, acoustic, pressure, temperature, humidity and other physical quantities.

AP Corp. applies, specifies, and supports the sales of Crystal Instruments products in Connecticut, Massachusetts, Vermont, Rhode Island, New Hampshire, and Maine.

AP Corp.

https://a-pcorp.com

(508) 351-6200

AP Corp. applies, specifies, and supports the sales of Crystal Instruments products in Connecticut, Massachusetts, Vermont, Rhode Island, New Hampshire, and Maine.

AP Corp.

https://a-pcorp.com

(508) 351-6200

Occupational Health & Environmental Sound and Vibration Meter: The SVAN 977A

The SVAN 977A is a class-one sound and vibration level meter that offers unprecedented state-of-the-art technology designed for general acoustic, occupational health, and building acoustic measurements of vibration and environmental noise. The instrument comes equipped as standard with the SV7052E polarized half inch microphone, the SV12 microphone preamplifier, and the SA22 foam windscreen, as well as a large 16 gigabyte internal memory which can be easily upgraded by a micro SD card. The meter comes equipped with a standard quarter inch photographic thread. On the bottom panel you can locate the usb serial and I/O sockets. There is also a micro SD card slot under the bottom cover and spaces for the four double a batteries. The SVAN 977A is equipped with a super contrast led color display. The instrument's user interface makes both configuration and measurement easier than ever before. The user can easily operate the instrument by selecting the appropriate position from the selected menu lists.

The instrument has 2 general modes of operation: Configuration mode; and measurement performance and results preview mode. The SVAN 977A can be used in the meter mode to perform the real-time 11 octave or 1/3 octave analysis including calculations of statistical levels, and can also perform FFT analysis. For building acoustic applications SVAN 977A offers reverberation time measurements RT60 and building acoustics assistant application for smartphones.

With a special microphone the meter provides measurement range of the ultrasounds up to 40 kilohertz. Measurement results can be viewed indifferent view modes, the set of which you can change and activate depending on the selected measurement function. If you disconnect the microphone preamplifier, you can use the instrument to take vibration measurements simply by connecting a cable and a vibration sensor. SVAN 977A can be easily installed into the SM277 case and used as an outdoor monitoring station thanks to a dedicated modem station which enables connection to the SVAN NET, an advanced server solution supporting remote connection giving users full access to the measurement data via web browser or dedicated application.

For more information, contact AP Corp. by visiting https://a-pcorp.com or by calling (508) 351-6200.

Labels:

Connecticut,

CT,

MA,

Maine,

Massachusetts,

ME,

New Hampshire,

New York,

NH,

NY,

Rhode Island,

RI,

Sound Meter,

SVAN977A,

Svantek,

Vermont,

vibration meter,

VT

US Power Grids, Oil and Gas Industries, and Risk of Hacking

A report released in June, from the security firm Dragos, describes a worrisome development by a hacker group named, “Xenotime” and at least two dangerous oil and gas intrusions and ongoing reconnaissance on United States power grids.

Multiple ICS (Industrial Control Sectors) sectors now face the XENOTIME threat; this means individual verticals – such as oil and gas, manufacturing, or electric – cannot ignore threats to other ICS entities because they are not specifically targeted.

The Dragos researchers have termed this threat proliferation as the world’s most dangerous cyberthreat since an event in 2017 where Xenotime had caused a serious operational outage at a crucial site in the Middle East.

The fact that concerns cybersecurity experts the most is that this hacking attack was a malware that chose to target the facility safety processes (SIS – safety instrumentation system).

For example, when temperatures in a reactor increase to an unsafe level, an SIS will automatically start a cooling process or immediately close a valve to prevent a safety accident. The SIS safety stems are both hardware and software that combine to protect facilities from life threatening accidents.

At this point, no one is sure who is behind Xenotime. Russia has been connected to one of the critical infrastructure attacks in the Ukraine. That attack was viewed to be the first hacker related power grid outage.

This is a “Cause for Concern” post that was published by Dragos on June 14, 2019.

“While none of the electric utility targeting events has resulted in a known, successful intrusion into victim organizations to date, the persistent attempts, and expansion in scope is cause for definite concern. XENOTIME has successfully compromised several oil and gas environments which demonstrates its ability to do so in other verticals. Specifically, XENOTIME remains one of only four threats (along with ELECTRUM, Sandworm, and the entities responsible for Stuxnet) to execute a deliberate disruptive or destructive attack.

XENOTIME is the only known entity to specifically target safety instrumented systems (SIS) for disruptive or destructive purposes. Electric utility environments are significantly different from oil and gas operations in several aspects, but electric operations still have safety and protection equipment that could be targeted with similar tradecraft. XENOTIME expressing consistent, direct interest in electric utility operations is a cause for deep concern given this adversary’s willingness to compromise process safety – and thus integrity – to fulfill its mission.

XENOTIME’s expansion to another industry vertical is emblematic of an increasingly hostile industrial threat landscape. Most observed XENOTIME activity focuses on initial information gathering and access operations necessary for follow-on ICS intrusion operations. As seen in long-running state-sponsored intrusions into US, UK, and other electric infrastructure, entities are increasingly interested in the fundamentals of ICS operations and displaying all the hallmarks associated with information and access acquisition necessary to conduct future attacks. While Dragos sees no evidence at this time indicating that XENOTIME (or any other activity group, such as ELECTRUM or ALLANITE) is capable of executing a prolonged disruptive or destructive event on electric utility operations, observed activity strongly signals adversary interest in meeting the prerequisites for doing so.”

In-Line Color Measurement for Recycled Plastic

|

| Photo 1 - Recycled Plastic with Color |

Color measurement is a well-accepted technology to check the quality of the color values in the production process. Usually these measurements are performed "off-line".

The delay between sampling and obtaining the results from the laboratory can be time consuming. A significant disadvantage is that only a single measurement is generated in this time period and the quality of the color during, before and after the sampling point is unknown.

With the in-line color measurements taking place directly in the melt, not only is complete documentation possible, but when color variations occur, immediate intervention can take place.

|

| Photo 2 - Reflection probe in strand pelletizer. |

INNOVATIVE NEW TECHNOLOGY

|

| Photo 4 - Stainless Steel NEMA4 box with touch-screen. |

Off-line measurements are used more effectively by downloading them to the Equitech Inline Color Spectrophotometer. This can be done manually or through OPC communications. By having the laboratory target values displayed on the Equitech system the operator can view trends of L*, a*, b* and Delta E.

This method provides complete documentation of a particular extrusion run. It also matches the known laboratory measurements giving confidence that an extrusion run has maintained specifications throughout its entirety. When color variations occur, notification can take place via digital alarms. Intervention can take place via OPC or analog signals i.e. L* feedback for closed loop color control.

|

| Photo 3 - Trend charts of EquiColor Software |

Illumination of the polymer through the sapphire window is achieved by 6 circumferentially-positioned glass fibers which convey the light of a xenon flash lamp. The reflection from the illuminated surface is detected by one center-positioned optical fiber. This reflected light is then interpreted by the spectrophotometer. Color values such as L*, a*, b* C*, h are calculated from this spectral curve, and displayed as trend charts, (see Photo 3).

For a continuous process monitoring, 10 to 60 seconds is recommended as the measurement interval. Intervals as fast as 1 to 2 seconds are possible. The calibration of the spectrophotometer is designed specifically for the demands of the production process. Calibration can be done without interruption of the process.

USER BENEFITS

- Real-time information about process stability & quality

- Impact of speed changes on the quality of the extrusion

- Controlled color changes: start phase, end of run

- Avoid off-specification batches & waste production

- Detection of dosage elevations

- Optimized recipe formulation & process design

- Available feedback loop for L* closed loop control via feeder

- Comprehensive quality audit trail customer documentation

Reprinted with permission from Equitech International Corporation.

The Three Most Common Types of Temperature Sensors

|

| Various types and styles of temperature sensors (Pyromation). |

This post describes the three most popular temperature sensors, how they function, and where they are used.

THERMOCOUPLES

|

| Thermocouple illustration showing base metal designs with various types of junctions (Pyromation). |

effect. In the simplest terms, thermocouples produce a micro-voltage between two conductors - joined at each end and made of dissimilar metals - when one junction varies in temperature and the second junction (called the reference junction) is known and maintained at a constant temperature. The corresponding voltage produced at the sensing junction can be measured and directly correlated to the change in the sensing junction's temperature.

Thermocouples are popular and widely used in industrial and commercial temperate systems because they are:

- Cost-effective.

- Provide good accuracy.

- Have a sufficiently linear temperature-to-signal output curve.

- Are available in many different metal alloys for many different temperature ranges.

- Are easily interchangeable.

Thermocouples are commonly found in many industrial processes. Examples are the plastics industry, primary metals, power generation, kilns, industrial boilers, HVAC, gas turbine exhaust systems and and diesel engines. And because they are affordable and easy to produce, thermocouples are also used in many consumer applications, such as residential and commercial cooking and heating equipment.

RTDs

|

| Wire wound RTD (Image courtesy Wikipedia) |

RTD’s are popular because:

- They offer considerably higher accuracy and repeatability than thermocouples.

- Can be used up to 600 Deg. Celsius.

- Can be integrated directly on the part to be monitored.

|

| Thin-film RTD (Image courtesy of Wikipedia) |

THERMISTORS

Another very common temperature sensing device is the thermistor. Thermistors are also a resistance measuring device similar to RTD’s. However, instead of using a pure metal as the resistance element, thermistors employ a very inexpensive polymer or ceramic resistance element. While these materials are very cost-effective, the downside is the resistance-to-temperature output curve. The change in resistance to a corresponding temperature change is very non-linear, and as such, make thermistors' use practical only within a narrow temperature range.

Thermistors are very inexpensive and have a very fast response making them very attractive in applications where a narrow sensing range exists and cost is important. Thermistors also come in two varieties, PTC, or positive temperature coefficient, and NTC, or negative temperature coefficient. PTC's resistance increases with increasing temperature, while NTC's resistance decreases with increasing temperature.

Thermistors are used widely in food processing in digital thermostats, and for on-board temperature monitoring of electronics and circuit boards. They are also used widely in many consumer appliances.

For more information on any temperature sensing application, contact AP Corp and discuss your requirement with one of their experienced application experts. They can be reached at (508) 351-6200 or visit them at https://a-pcorp.com.

Dynisco Online Viscosity Measurement

From the Dynisco presentation "From lab to production, providing a window into the process."

Get maximize extrusion efficiency with Dynisco Online Rheological Testing.

Dynisco online rheometers provide a "window into your process" with the ability to continuously measure critical parameters form melt flow ratio to intrinsic / relative / melt viscosity and from constant shear rate to shear sweep.

The video above introduces the Dynisco ViscoSensor, CMR IV, and FCR and presents the viewer a cost justification for their use. You can also download the presentation from the AP Corp. website here.

For more information in New England and Upstate New York, contact AP Corp. by calling (508) 351-6200 or by visiting https://a-pcorp.com.

What are Plastics Industry Feed Screws and How Are They Made?

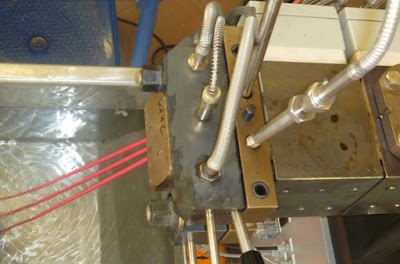

|

| Feed screw maintenance. |

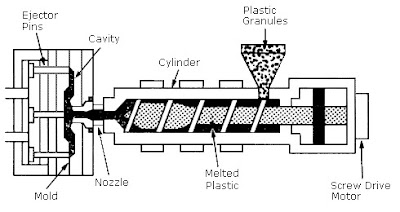

Plastics industry feed screws, or feed screw augers, are mechanisms that use rotating helical screw blades to move plastics pellets through the barrel of molding and extrusion equipment. The feed screw transports the plastic as it changes phase from solid to viscous liquid through friction, shear, and conductive heat transfer.

A typical feed screw has three zones. Plastic pellets enters the screw feed section where the pellets are compacted and conveyed. Next is the transition (or compression) section, where the plastic is compressed, conveyed, and melted. Finally, the liquid plastic moves to the metering section where it is precisely controlled at optimum temperature and viscosity.

For more information about feed screws, or any part of the injection molding process, contact:

508-351-6200

|

| Diagram of injection molding process. |

Strain Gage Sensors with Pre-attached Lead Wires

508-351-6200

Labels:

C4A,

C5K,

Micro-Measurements,

New England,

Strain Gages,

Upstate New York

For Strain Gage Users Who Hate to Solder - New Strain Gage Sensors with Pre-attached Leads

The following is the transcript from the podcast "StrainBlog" (https://www.strainblog.com) about exciting new technology for adding lead wires to strain gages. The discussion between hosts Jim and Darryl is about the development and virtues of the new Advanced Sensors Technology C4A and C5K strain gages.

Jim - The topic that keeps coming up repetitively is gauges with pre-attached lead wires. I got a myriad of customers looking for a variety of different solutions. Everything from printed circuit boards, where we've got to route very fine lead wires from gauges to data acquisition systems; civil engineering projects where they're looking for low cost, long cable lengths, sometimes two wires, sometimes three wire. There seem to be more and more demands - what are we doing to meet this variety of applications that we sort of lump into this category of pre-leaded strain gages?

Darryl - Jim, that's a fantastic question. So, we've got this new line of strain gages we call C4A's [from Micro-Measurements], and they they're available in a bunch of different sizes. We go down right now to about a 0.062" gage length, and we go up to a 0.235" gage length. We put a two conductor and a three conductor wire on it on. We can vary the length of that, and these gages are actually made using our new technology from the Advanced Sensors Group, where we can really push the limits now both on the size of the strain gage as well as the resistance. We're really excited about these. We're targeting different markets, including structural testing, as well as printed circuit board testing. There's also another one that we've recently introduced, which is a C5K version, and that's a three element rosette, a planar style that's in a 350 Ohm resistance, and with this new technology, we can make this gauge smaller, more compact than ever before, and it really makes it ideal for printed circuit board testing, where you're trying to get up close to the components that's on that board, so that you could get very accurate, localized strain gage measurements.

Jim - Now, I think I've seen one of the C5K gages that you refer to, and that's a remarkably small planar gage. If I'm correct, the footprint of that planar gage is even smaller than the smallest stacked rosette that we've ever made. Is that true?

Darryl - Yeah, you're absolutely right. So, one of the smallest stacked rosettes we've had is the 031WW as well as the G1350, and this new planar gage will actually fit within the footprint of both of those gages. The active gauge length is less than 0.020 of an inch, and we also pre-attach three conductor, 36 gauge wire to each one of those grids, so basically, you have a planar rosette with 10 feet of three conductor Teflon insulated wire that's 36 gauge in size.

Jim - Well that seems to solve a lot of problems. With stacked rosette that you have a lot of self heating issues, trying to dissipate the heat from those three layers, down to a single plane and dissipate that. With the planar rosette, all gauges air on the single plane - you don't have a proximity issue with height of sight from the neutral axis, you don't have that heat build up, and if I remember correctly, these are actually 350 Ohm gages, not 120.

Darryl - That's absolutely right. You hit the nail on the head. These are 350 Ohm gages, so you don't have to be as concerned about self heating effects, because of the higher resistance, and also because it's a planar, and like you mentioned, there's not as much of a superposition error because that's a planar gage and not a stack one. So there should be less correction due to bending and also less concern related to excitation and self-heating of the strain gage. We're really excited about adding this to our portfolio of strain gauges that customers can use now to do this printed circuit board type testing.

Jim - And that coupled with the fine wires solves a wire routing issue, getting those leads out from between components out of the package to the data acquisition system. Sounds like a perfect solution to me.

Darryl - Yeah, we're really excited about.

For more information on strain gage sensors with pre-attached leads in New England or Upstate New York, contact AP Corp. by calling (508) 351-6200 or visit their website at https://a-pcorp.com.

White Paper: Learn Why Eddy-Current Sensors Are Now Replacing Inductive Sensors and Switches

Recent advances in eddy-current sensor design, integration and packaging, as well as overall cost reduction, have made these sensors a much more attractive option than inductive sensors. This is especially true where high linearity, high-speed measurements and high resolution are critical requirements.

This white paper, courtesy of Micro Epsilon and AP Corp, explains why.

This white paper, courtesy of Micro Epsilon and AP Corp, explains why.

AP Corp

(508) 351-6200

An Introduction to Sentek Dynamics Vibration Testing Systems

|

| Download the full paper here. |

Although this paper focusses on Sentek Dynamics products, it provides excellent details about shaker technology in general.

Get the full Sentek Dynamics Vibration Testing Systems Introduction paper at this AP Corp. web page.

Check Out the Current AP Corp. Line Sheet

AP Corp. represents the top manufactures of industrial sensors and instrumentation. Product categories include Analyzers, Color Sensors, Displacement Sensors, Flow Sensors, Instrumentation (Data Acquisition), Load Cells & Instrument Hardware, Machine Controls, Pressure Gauges, Pressure Sensors, Sanitary Sensors, Sound Sensors, Strain Gages, Temperature Sensors, and Vibration Sensors. As one of New England's and New York's premier Manufacturer's, AP Corp. will assist you in selecting the perfect sensor for your application.

Check out the AP line sheet by reviewing the embedded document below, or you can download a PDF line sheet from this page on the AP Corp. web site.

AP Corp.

https://a-pcorp.com

(508) 351-6200

Check out the AP line sheet by reviewing the embedded document below, or you can download a PDF line sheet from this page on the AP Corp. web site.

AP Corp.

https://a-pcorp.com

(508) 351-6200

Dynisco ViscoSensor for Online Rheological Measurement

|

| Dynisco ViscoSensor for the thermoplastics resin industry. |

Designed for the thermoplastics resin market, the Dynisco ViscoSensor provides the continuous measurement of melt flow rate, or apparent or intrinsic viscosity, directly on the manufacturing process.

To learn more about online rheological measurement with the Dynisco ViscoSensor visit this page on the AP Corp website.

Andruss-Peskin (AP) Corporation

(508) 351-6200

https://a-pcorp.com

Three Types of Common Industrial Sensors: Inductive, Capacitive, and Photoelectric

Three common industrial sensors are inductive proximity sensors, capacitive proximity sensors, and photoelectric sensors.

Inductive sensors can detect a target from 0.5 millimeters to 40 millimeters. They only detect metallic targets and therefore use a magnetic field to detect presence when a ferrous metal enters the magnetic field.

Capacitive proximity sensors on the other hand can detect dielectric materials such as liquids plastic glass, wood and granulated substances as long as it has a dielectric constant of 1.2 or more. Their range is from three millimeters to 15 millimeters depending on the dielectric material to be detected.

Photoelectric sensors have the greatest detection range from one millimeter to 25 meters or more. They operate by the use of an emitter which transmits a beam of light to the receiver. They operate by detecting the presence, or absence, of a light beam sent from transmitter to receiver.

These are three very basic sensor technologies used in many common applications. The video above provides an elementary understanding of the operational differences.

For more information on any industrial or OEM sensor, contact AP Corporation by visiting https://a-pcorp.com or by calling 508-351-6200

The SVAN 971 Class 1 Sound Level Meter

The SVAN 971 is a Class 1 sound level meter and real-time analyzer. It is an ideal choice for industrial hygiene noise measurements, short period environmental noise measurements, acoustics consultancy surveys, technical engineers dealing with noise issues, and general acoustics noise measurements.

The SVAN 971 is an extremely small instrument with options for 1/1 & 1/3 octave analysis. The instrument brings unprecedented state of the art technology to a SLM of this size.The user interface makes both configuration and measurement easier than ever before. For those who don't have time to work with measurement settings, SVAN 971 offers extremely simple operational mode with Start/Stop. Another exceptional feature is built-in self-vibration monitoring providing information about level of vibration that influences the measurement results.

For more information, contact:

Andruss-Peskin Corporation

https://www.a-pcorp.com

(508) 351-6200

Labels:

Connecticut,

CT,

Industrial Noise,

MA,

Maine,

Massachusetts,

ME,

New Hampshire,

New York,

NH,

NY,

Rhode Island,

RI,

Sound Meter,

SVAN 971,

Svantek,

Vermont,

VT

Welcome to the Sensor and Instrumentation Blog of New England

Thanks for visiting! It's our intention to feature products, technologies, and concepts of interest to the sensor and instrumentation community. Subjects will include all types of industrial sensors and instrumentation, basics of operation, and new exciting products.

Among the products and applications we will feature are: analyzers, color sensors, displacement sensors, flow sensors, industrial weighing, instrumentation (data acquisition), load cells & instrument hardware. machine controls, pressure gauges, pressure sensors, sanitary sensors, strain gages, and temperature sensors.

We hope you enjoy and visit back frequently!

Among the products and applications we will feature are: analyzers, color sensors, displacement sensors, flow sensors, industrial weighing, instrumentation (data acquisition), load cells & instrument hardware. machine controls, pressure gauges, pressure sensors, sanitary sensors, strain gages, and temperature sensors.

We hope you enjoy and visit back frequently!

Subscribe to:

Posts (Atom)