Flameless, non-contact induction heating minimizes energy waste by focusing energy only on the part and zone to be heated. Select and monitor power levels from the front panel LCD and sealed touch pad. Remote power control is available for employing contact inputs, analog inputs or optional serial data port. Easily control the length of the heating cycle with a built-in programmable digital timer.

A blog discussing sensors and instrumentation. New products, new technologies, and interesting applications. Types of sensors and instruments discussed include: Analyzers, Color Sensors, Displacement Sensors, Flow Sensors, Industrial Weighing, Instrumentation (Data Acquisition), Load Cells & Instrument Hardware. Machine Controls, Pressure Gauges, Pressure Sensors, Sanitary Sensors, Strain Gages, and Temperature Sensors. Courtesy of AP Corp.

EASYHEAT Induction Heaters from Ambrell Corporation

New Bench Top Series of Shaker Systems from Sentek Dynamics

The BT Series shakers from Sentek Dynamics are designed for demanding vibration test applications. Typical applications included structural analysis, calibration and testing of smaller assemblies. The BT-100 through BT-400 shakers utilize light weight rare earth magnets in lieu of traditional Alnico magnets. The use of these magnets decreases the total shaker mass to a third of similar size system, making these shakers easy to handle and portable.

The systems range in size from 100 N (70 lbf) to 1000 N (224 lbf). Systems 400 N (99 lbf) and smaller are permanent magnet shakers and use lightweight rare earth magnets, making these systems easy to handle and portable. There are three versions of the BT Series of shakers: the BT, BT-M and BT-MTH.

The BT Series is recommended for vibration testing of small assemblies and components. These shakers have armature diameters from 60 mm (2.36 in.) to 120 mm (4.72 in.). The BT-1000 is equipped as standard with Automatic Armature Centering (AAC) and Air-Isolation Feet (AIF).

The BT-M and BT-MTH Series are our modal shakers lines. BT-M will use standard stingers while the BT-MTH is our through-hole version. On the 100 N and 200 N system the BT-MTH offers over double the displacement. The BT-MTH Series allow you to use piano-wire stingers. The BT-1000-M is ideal for the structural and modal analysis of high-mass structures. The addition of ZPR (electronic zero-point regulation and adjustable suspension stiffness) allows the user to pre-load the structure prior to applying a dynamic load.

The new Sentek Dynamics Bench Top and modal exciters are based upon years of practical experience. These systems all exhibit a high lateral stiffness and high force-to-weight ratio. They are specifically designed to help ensure the best possible performance with minimum setup time.

Contact AP Corp. regarding any Sentek Dynamics product in New England and Upstate New York. Call us at (508) 351-6200 or visit our website at https://a-pcorp.com.

Micro-Epsilon Laser Profile Scanners: scanCONTROL LLT3000 and 2500

Micro-Epsilon scanCONTROL LLT3000

Micro-Epsilon scanCONTROL 2500

BLH Nobel KIS Beam Load Cell Technology

In-Line Turbidity and Haze Measurement

|

| Photo 1: Equitech's Retro-Reflection Probe |

|

| Photo 3: Trend charts of EquiColor Software |

|

| Photo 2: ICS stainless steel NEMA4 box with touch-screen |

What is a Binocular Strain Gauge Load Cell?

Load Cells for Weighing Vessels in Hot and Vibration Prone Areas

A case in point is a chemical manufacturer with several, existing three cubic meter batching tanks. It was decided the tanks needed modifications to provide more accurate weighing of the individual ingredients. The existing load cells were experiencing errors due to thermal expansion of the vessel, and the resultant side loads from expansion. Additionally there was a problem with vibration in the plant. A better solution was needed, and whatever the solution would be, the customer made it clear the new weighing system must provide system accuracy in the range of ±0.1%.

An approach to deal mechanically with the thermal cycling while using the same type of load cell was discussed. It involved several mechanical modifications that required significant and costly structural changes.

|

| BLH KIS |

|

| BLH Controller |

For more information on BLH Nobel products in New England and Upstate New York contact A-P Corp. Call them at (816) 353-6550 or visit them at https://a-pcorp.com.

Polymer Analysis Using ASTM/ISO Method A Testing and the Dynisco LMI5500 Melt Flow Indexer

The LMI5500 Series Melt Flow Indexer from Dynisco

The LMI5500 provides a new level of simplicity of use with its simple to clean inspection plate, accessibility for sample cutting, and improved touchscreen display.

Most notable is its own gravitational correction characteristic that takes into consideration gravity according to the units geographic location.

It is capable of delivering a wide range of data for melt flow rate, shear stress, shear rate, apparent viscosity, intrinsic viscosity, melt density, and testing conditions.

FEATURES OF THE DYNISCO LMI5500 SERIES MELT FLOW INDEXER

- Gravitational correction

- New Windows 10 IoT touch screen native interface

- Built in WIFI and ethernet

- HDMI and multiple USB ports

- Direct digital scale USB interface for sample weighing

- Performance meets international standards: ASTM D1238 & D3364, ISO 1133-1, BS2782, DIN 53735, JIS K7210

- Automatic sample cutter for ease and consistency in sample cutting

- Melt Flow Rate to Intrinsic Viscosity correlation for PET

- Nearly unlimited program storage capability

- Increased access to the die for sample cutting with a strategically placed mirror to easily view the die and cutting area

- Supports multiple languages

For more information about the Dynisco LMI5500 Series Melt Flow Indexer in New England and Upstate New York, contact AP Corporation by calling (508) 351-6200 of visit their web site at https://a-pcorp.com.

Gas Turbine Monitoring with Kistler Pressure and Acceleration Sensors

AP Corporation is pleased to present Gas Turbine Monitoring with Kistler Pressure and Acceleration Sensors

Kistler high-temperature measuring systems allow measuring thermoacoustics phenomena in harsh environments with extreme temperatures up to 700°C.

- Safe and reliable operation of gas turbines thanks to combustion dynamics monitoring.

- Differential charge amplifier designed for high temperature sensors.

- High temperature acceleration sensors measuring vibrations.

- High temperature pressure sensors measuring pressure pulsations.

- Reliable monitoring with durable sensors in harsh environments and up to 700°C / 1300°F.

- Predict, monitor and analyze combustion dynamics.

- Complete differential, ground insulated measuring chains enable early detection of smallest pressure pulsations.

- Resistant to high temperature (700°C / 1300°F)

- Ex certified and interference resistant (EMI, RF)

- PiezoStar sensing element - not pyroelectric and no popcorn effect

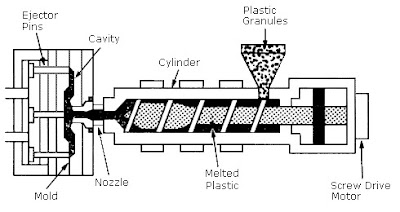

Why Plastics Industry Feed Screws are Designed the Way They Are

|

| Download the white paper here. |

The selection of the proper screw for a given injection molding or extrusion application can be critical to its success.

Screw geometry — length-to-diameter ratio, profile, channel depth, compression ratio, helix angle and a host of special design features — has everything to do with how well the screw performs in a given application.There are documented applications where customers have improved production rates or reduced cycle times by 30 or 40% simply by switching to an improved screw design. Similarly, reject rates have been lowered from more than 4-6% to less than 1% by incorporating a custom designed mixing screw.

And experience shows that the amount of color concentrate required to achieve optimum color mix can be typically reduced from 4% (of the total blend) to 2%, just by using an optimized screw design. When considering resin and concentrate costs, payback for an optimized screw and non-return valve design can be almost immediate.

This white paper, published by Glycon Corporation, provides an in-depth look into plastics industry feed screw design.

In-Line Color Measurement for Recycled Plastic

|

| Photo 1 - Recycled Plastic with Color |

Color measurement is a well-accepted technology to check the quality of the color values in the production process. Usually these measurements are performed "off-line".

The delay between sampling and obtaining the results from the laboratory can be time consuming. A significant disadvantage is that only a single measurement is generated in this time period and the quality of the color during, before and after the sampling point is unknown.

With the in-line color measurements taking place directly in the melt, not only is complete documentation possible, but when color variations occur, immediate intervention can take place.

|

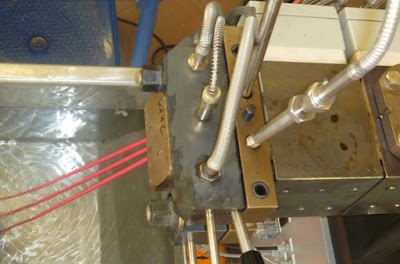

| Photo 2 - Reflection probe in strand pelletizer. |

INNOVATIVE NEW TECHNOLOGY

|

| Photo 4 - Stainless Steel NEMA4 box with touch-screen. |

Off-line measurements are used more effectively by downloading them to the Equitech Inline Color Spectrophotometer. This can be done manually or through OPC communications. By having the laboratory target values displayed on the Equitech system the operator can view trends of L*, a*, b* and Delta E.

This method provides complete documentation of a particular extrusion run. It also matches the known laboratory measurements giving confidence that an extrusion run has maintained specifications throughout its entirety. When color variations occur, notification can take place via digital alarms. Intervention can take place via OPC or analog signals i.e. L* feedback for closed loop color control.

|

| Photo 3 - Trend charts of EquiColor Software |

Illumination of the polymer through the sapphire window is achieved by 6 circumferentially-positioned glass fibers which convey the light of a xenon flash lamp. The reflection from the illuminated surface is detected by one center-positioned optical fiber. This reflected light is then interpreted by the spectrophotometer. Color values such as L*, a*, b* C*, h are calculated from this spectral curve, and displayed as trend charts, (see Photo 3).

For a continuous process monitoring, 10 to 60 seconds is recommended as the measurement interval. Intervals as fast as 1 to 2 seconds are possible. The calibration of the spectrophotometer is designed specifically for the demands of the production process. Calibration can be done without interruption of the process.

USER BENEFITS

- Real-time information about process stability & quality

- Impact of speed changes on the quality of the extrusion

- Controlled color changes: start phase, end of run

- Avoid off-specification batches & waste production

- Detection of dosage elevations

- Optimized recipe formulation & process design

- Available feedback loop for L* closed loop control via feeder

- Comprehensive quality audit trail customer documentation

Reprinted with permission from Equitech International Corporation.

The Three Most Common Types of Temperature Sensors

|

| Various types and styles of temperature sensors (Pyromation). |

This post describes the three most popular temperature sensors, how they function, and where they are used.

THERMOCOUPLES

|

| Thermocouple illustration showing base metal designs with various types of junctions (Pyromation). |

effect. In the simplest terms, thermocouples produce a micro-voltage between two conductors - joined at each end and made of dissimilar metals - when one junction varies in temperature and the second junction (called the reference junction) is known and maintained at a constant temperature. The corresponding voltage produced at the sensing junction can be measured and directly correlated to the change in the sensing junction's temperature.

Thermocouples are popular and widely used in industrial and commercial temperate systems because they are:

- Cost-effective.

- Provide good accuracy.

- Have a sufficiently linear temperature-to-signal output curve.

- Are available in many different metal alloys for many different temperature ranges.

- Are easily interchangeable.

Thermocouples are commonly found in many industrial processes. Examples are the plastics industry, primary metals, power generation, kilns, industrial boilers, HVAC, gas turbine exhaust systems and and diesel engines. And because they are affordable and easy to produce, thermocouples are also used in many consumer applications, such as residential and commercial cooking and heating equipment.

RTDs

|

| Wire wound RTD (Image courtesy Wikipedia) |

RTD’s are popular because:

- They offer considerably higher accuracy and repeatability than thermocouples.

- Can be used up to 600 Deg. Celsius.

- Can be integrated directly on the part to be monitored.

|

| Thin-film RTD (Image courtesy of Wikipedia) |

THERMISTORS

Another very common temperature sensing device is the thermistor. Thermistors are also a resistance measuring device similar to RTD’s. However, instead of using a pure metal as the resistance element, thermistors employ a very inexpensive polymer or ceramic resistance element. While these materials are very cost-effective, the downside is the resistance-to-temperature output curve. The change in resistance to a corresponding temperature change is very non-linear, and as such, make thermistors' use practical only within a narrow temperature range.

Thermistors are very inexpensive and have a very fast response making them very attractive in applications where a narrow sensing range exists and cost is important. Thermistors also come in two varieties, PTC, or positive temperature coefficient, and NTC, or negative temperature coefficient. PTC's resistance increases with increasing temperature, while NTC's resistance decreases with increasing temperature.

Thermistors are used widely in food processing in digital thermostats, and for on-board temperature monitoring of electronics and circuit boards. They are also used widely in many consumer appliances.

For more information on any temperature sensing application, contact AP Corp and discuss your requirement with one of their experienced application experts. They can be reached at (508) 351-6200 or visit them at https://a-pcorp.com.

Dynisco Online Viscosity Measurement

From the Dynisco presentation "From lab to production, providing a window into the process."

Get maximize extrusion efficiency with Dynisco Online Rheological Testing.

Dynisco online rheometers provide a "window into your process" with the ability to continuously measure critical parameters form melt flow ratio to intrinsic / relative / melt viscosity and from constant shear rate to shear sweep.

The video above introduces the Dynisco ViscoSensor, CMR IV, and FCR and presents the viewer a cost justification for their use. You can also download the presentation from the AP Corp. website here.

For more information in New England and Upstate New York, contact AP Corp. by calling (508) 351-6200 or by visiting https://a-pcorp.com.

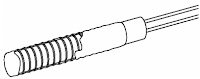

What are Plastics Industry Feed Screws and How Are They Made?

|

| Feed screw maintenance. |

|

| Diagram of injection molding process. |

Strain Gage Sensors with Pre-attached Lead Wires

508-351-6200

For Strain Gage Users Who Hate to Solder - New Strain Gage Sensors with Pre-attached Leads

The following is the transcript from the podcast "StrainBlog" (https://www.strainblog.com) about exciting new technology for adding lead wires to strain gages. The discussion between hosts Jim and Darryl is about the development and virtues of the new Advanced Sensors Technology C4A and C5K strain gages.

Jim - The topic that keeps coming up repetitively is gauges with pre-attached lead wires. I got a myriad of customers looking for a variety of different solutions. Everything from printed circuit boards, where we've got to route very fine lead wires from gauges to data acquisition systems; civil engineering projects where they're looking for low cost, long cable lengths, sometimes two wires, sometimes three wire. There seem to be more and more demands - what are we doing to meet this variety of applications that we sort of lump into this category of pre-leaded strain gages?

Darryl - Jim, that's a fantastic question. So, we've got this new line of strain gages we call C4A's [from Micro-Measurements], and they they're available in a bunch of different sizes. We go down right now to about a 0.062" gage length, and we go up to a 0.235" gage length. We put a two conductor and a three conductor wire on it on. We can vary the length of that, and these gages are actually made using our new technology from the Advanced Sensors Group, where we can really push the limits now both on the size of the strain gage as well as the resistance. We're really excited about these. We're targeting different markets, including structural testing, as well as printed circuit board testing. There's also another one that we've recently introduced, which is a C5K version, and that's a three element rosette, a planar style that's in a 350 Ohm resistance, and with this new technology, we can make this gauge smaller, more compact than ever before, and it really makes it ideal for printed circuit board testing, where you're trying to get up close to the components that's on that board, so that you could get very accurate, localized strain gage measurements.

Jim - Now, I think I've seen one of the C5K gages that you refer to, and that's a remarkably small planar gage. If I'm correct, the footprint of that planar gage is even smaller than the smallest stacked rosette that we've ever made. Is that true?

Darryl - Yeah, you're absolutely right. So, one of the smallest stacked rosettes we've had is the 031WW as well as the G1350, and this new planar gage will actually fit within the footprint of both of those gages. The active gauge length is less than 0.020 of an inch, and we also pre-attach three conductor, 36 gauge wire to each one of those grids, so basically, you have a planar rosette with 10 feet of three conductor Teflon insulated wire that's 36 gauge in size.

Jim - Well that seems to solve a lot of problems. With stacked rosette that you have a lot of self heating issues, trying to dissipate the heat from those three layers, down to a single plane and dissipate that. With the planar rosette, all gauges air on the single plane - you don't have a proximity issue with height of sight from the neutral axis, you don't have that heat build up, and if I remember correctly, these are actually 350 Ohm gages, not 120.

Darryl - That's absolutely right. You hit the nail on the head. These are 350 Ohm gages, so you don't have to be as concerned about self heating effects, because of the higher resistance, and also because it's a planar, and like you mentioned, there's not as much of a superposition error because that's a planar gage and not a stack one. So there should be less correction due to bending and also less concern related to excitation and self-heating of the strain gage. We're really excited about adding this to our portfolio of strain gauges that customers can use now to do this printed circuit board type testing.

Jim - And that coupled with the fine wires solves a wire routing issue, getting those leads out from between components out of the package to the data acquisition system. Sounds like a perfect solution to me.

Darryl - Yeah, we're really excited about.

For more information on strain gage sensors with pre-attached leads in New England or Upstate New York, contact AP Corp. by calling (508) 351-6200 or visit their website at https://a-pcorp.com.

White Paper: Learn Why Eddy-Current Sensors Are Now Replacing Inductive Sensors and Switches

This white paper, courtesy of Micro Epsilon and AP Corp, explains why.

An Introduction to Sentek Dynamics Vibration Testing Systems

|

| Download the full paper here. |

Although this paper focusses on Sentek Dynamics products, it provides excellent details about shaker technology in general.

Check Out the Current AP Corp. Line Sheet

Check out the AP line sheet by reviewing the embedded document below, or you can download a PDF line sheet from this page on the AP Corp. web site.

AP Corp.

https://a-pcorp.com

(508) 351-6200